FutuRaM Annual Event in October 2025

Pencil 22-23 October in your calendars, the next FutuRaM annual event will take place in Tutzing, Germany! More details on the agenda will follow soon.

FutuRaM Consortium Gathers in Skellefteå

At the end of June, the FutuRaM project convened its bi-annual consortium meeting in Skellefteå, a historic mining town nestled in the north of Sweden. With nearly 50 participants in attendance, the meeting brought together project partners from across Europe for thorough discussions, in-depth case studies, and unique field experiences - followed by a tour through the local mining landscape.

FutuRaM at UNECE Resource Management Week in Geneva

On 26 March 2025, the second annual event of FutuRaM took place as part of the UNECE Resource Management Week at the United Nations office in Geneva. Over 50 experts gathered to learn more about the project and its first results.

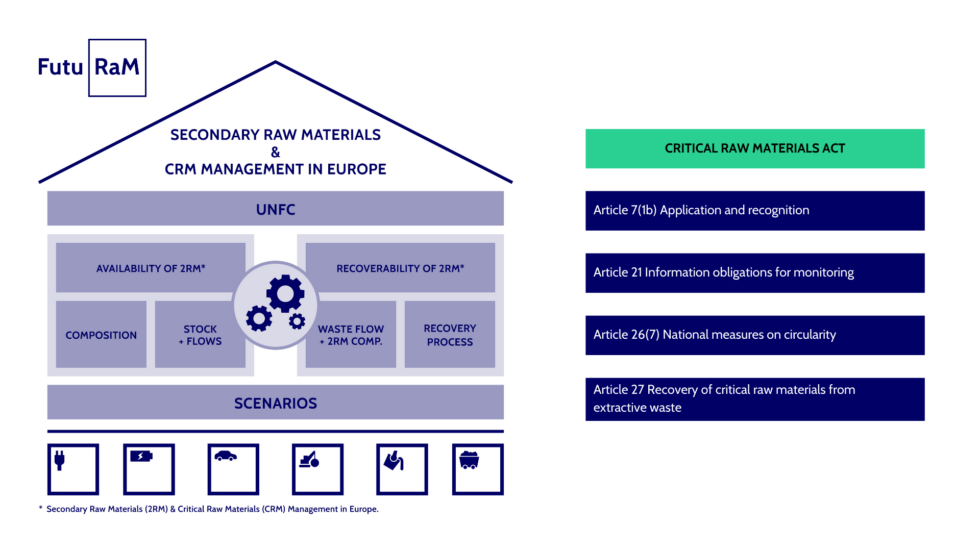

Kirsten Remmen of Empa introduced FutuRaM by explaining that the main motivation of the project is to emphasize the importance of reliable and complete data to model future secondary raw material stocks and flows to support legislation (e.g. the CRM Act). She also explained how the project identifies where the elements are in products by gathering data on the components and materials in which the elements are found; this is essential for improving the recovery potential. Finally, she outlined the three scenarios developed in FutuRaM as it plots changes in stocks and flows of materials to 2050 i.e. ‘Business-as-usual’, ‘Recovery’ and ‘Circularity’.

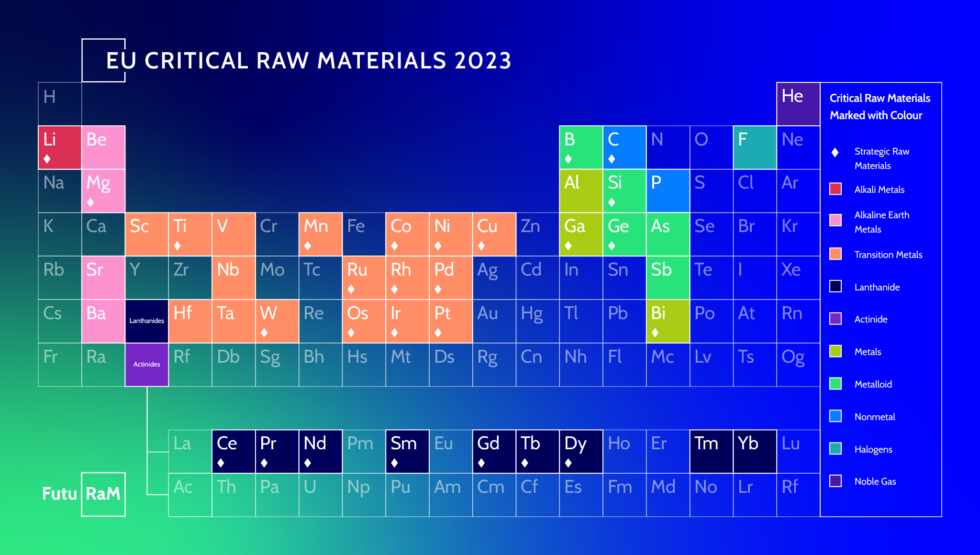

Kees Baldé of UNITAR revealed some of the first results of the data gathering process and how these could be useful to stakeholders wishing to understand more about the elements contained in products and where these might be found. He also outlined what the initial FutuRaM results tell us about which elements occur in the greatest quantities of the focus waste streams as well as those elements that occur in significant quantities relative to global extraction e.g. dysprosium, palladium and platinum all occur in end-of-life vehicles in quantities that are significant when viewed beside global demand.

The work on the recovery potential was also discussed as it is noted that in many cases only a small proportion of a critical raw material in a waste stream can be recovered due to recovery and collection losses, although this remains an important opportunity. To take the example of Neodymium: there are an estimated 1,200 tonnes of it sitting in European electronics waste, and although it is estimated that just 88 tonnes could potentially be recovered by 2030, this is still a significant and useful amount.

Soraya Heuss-Aßbichler, Professor of Mineralogy and Petrology at LMU showed how the UNFC methodology is being applied in practice to anthropogenic resources through FutuRaM case studies. FutuRaM is undertaking 19 case studies to test the UNFC methodology on secondary raw material projects and four of these were presented at the event:

- Mining waste case study by Ronald Arvidsson of SGU

- Timber recovery by Jonas Breidenbach of UCL

- Phosphorous recovery by Soraya Heuss-Aßbichler

- Battery recycling by her colleague Iman Dorri

In a panel session, Stéphane Bourg (OFREMI, BRGM, France) Kieran Campbell-Johnston (TNO, Netherlands) and Minja Marijanski (Proman Management, Austria) discussed, under the moderation of Erika Ingvald of UNECE, how FutuRaM can be useful to the national CRM Observatories established in Member States and with policy makers. Within this discussion it was suggested that building on and expanding the FutuRaM work after the end of the project will be important in assisting the CRM Observatories to fulfil their future ambitions.

The European Critical Raw Materials Act from a FutuRaM Perspective

The European Union has enforced its Critical Raw Materials Act (CRMA) in record time. What started with the publication of the European Commission´s proposal on 16 March 2023 was immediately picked up by the Council of the European Union and by the European Parliament in various committees under the Swedish presidency. The final approval by the Council for a strategy to secure a sustainable supply of raw materials critical for the green transition, digital industries, and defense sectors was achieved within one year by Monday by 18 March 2024. Upon the publication in the Official Journal on 3 May 2024 the CRMA entered into force on 23 May 2024.

The CRMA aims to strengthen the European critical raw materials capacities along all stages of the value chain and hence, the resilience of its critical raw material supply chains by reducing dependencies, making preparations and promoting supply chain sustainability and circularity.

CRMA Benchmarks

The benchmarks set to be reached by 2030 provide further guidance on priorities. In a nutshell, domestic capacities along the strategic raw material supply chain and for diversifying EU supply shall meet at least EU’s annual consumption:

The promotion of a sustainable and circular economy aims also to improve the availability of critical raw materials. Hence, a strong secondary market is key to meet the ambitious benchmarks of 25% referring to the Union’s recycling capacity. Two requirements tie this up:

- First and foremost, knowing the occurring and available stocks, waste streams and their composition. With this knowledge, recoverable waste streams containing the critical/strategic raw materials can be targeted.

- Secondly, the European Union needs to support the framework and infrastructure for recycling facilities and processes to achieve this benchmark.

FutuRaM’s Supporting Role

FutuRaM has already begun addressing the first requirement by developing a knowledge base for six specific waste streams: batteries, electrical and electronic equipment, vehicles, mining, slags and ashes, and construction and demolition. As we speak, the composition of the mentioned waste streams is being analysed based on a large number of datasets. Looking ahead, FutuRaM results will enable the prioritisation of existing waste streams containing a high percentage of recoverable strategic raw materials on a European level.

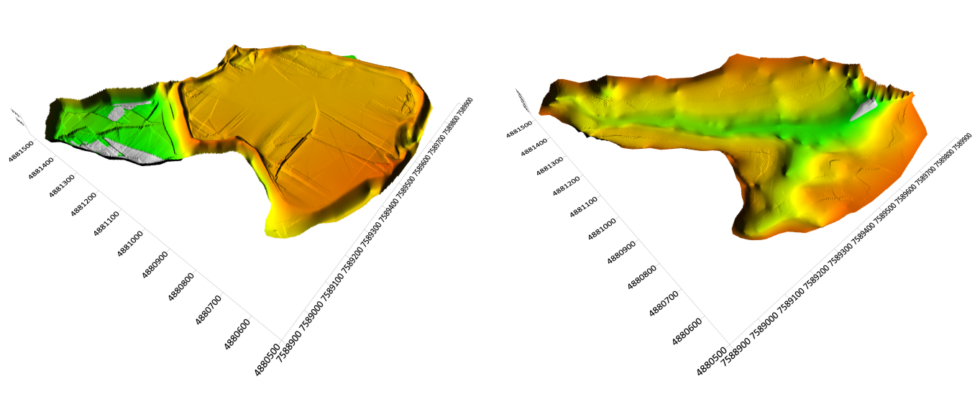

Insights from the Otanmäki Ilmenite Tailings Storage Facility Project

In recent years, the growing demand for Critical Raw Materials (CRMs) has led to increased interest in extracting valuable resources from industry side streams, such as mine tailings. A new FutuRaM project study by the Geological Survey of Finland (GTK) focuses on the Otanmäki tailings storage facility (TSF) in Finland, which contains ilmenite, a crucial mineral for various industries. The research aims to evaluate the resource potential of the Otanmäki TSF and compare different sampling methodologies to ensure accurate and representative data collection.

Valorisation of Old Flotation Tailings from Copper Ore Processing: a FutuRaM Mine Waste Case Study

One of the FutuRaM case studies focuses on the Old Flotation Tailings (OFT) in Bor (Serbia) exploring how this waste could be repurposed and given new life. The exploration of the broader Bor metallogenetic zone has facilitated over a century of copper ore extraction, yielding significant quantities of copper metal, sulphur (processed into sulfuric acid), as well as gold and silver. However, this extensive mining activity has also led to the accumulation of approximately 207 million tons (Mt) of flotation tailings, 450 Mt of overburden, and 23 Mt of slag within the Bor municipality. The oldest flotation tailings (OFTs), which are used as FutuRaM case study, were generated during the first stages of copper mining and production in Bor. During that time, the high-grade parts of the ore body were extracted and processed, and it is expected that these flotation tailings contains metals in grades high enough to enable their economical extraction.

Extraction of Secondary Critical Raw Materials from Historical Mining Waste – First Trials at the Håkansboda Historical Mine, Bergslagen Sweden

Lovisagruvan AB is one of the 28 partners in the FutuRam consortium and is an operating zinc-lead and silver producing mine in South Central Sweden. Lovisagruvan also has interests in the nearby Håkansboda historical mining area where copper, cobalt, gold and silver have been extracted between 1328 and 1912.

Amongst the widespread piles of waste rock, it is easy to find specimens that contain minerals that in turn contain copper, cobalt, silver, zinc, iron, and other more exotic elements like bismuth, antimony, molybdenum, and even some gold, as well as deleterious elements like arsenic. It is easy to imagine that some of these specimens “must be” worth extraction, but is it realistic?

Tap Into Our Knowledge Base

Learn more from our experts sharing their knowledge on a regular basis on our website.

Join the FutuRaM Stakeholder Network

A crucial part of the FutuRaM project will be the input of stakeholders from all parts of the value chain. The project needs to be in touch with interested individuals and organisations to get their input on the many facets of the work it is undertaking. If you are involved in work on any of the focus waste streams, have an interest in CRMs and SRMs, would like to share your thoughts and experiences on the application of the UNFC for Resources methodology, or work in relevant areas of data, statistics, or investment, then we would be grateful for your input. It may be that you only want to keep in touch.

This project is funded by the European Union under the Horizon Europe Research and Innovation Programme. The contents of this newsletter only reflect the views of the project.